ความเร็วและความปลอดภัยคือทุกอย่างเมื่อพูดถึงการทำธุรกรรมเงินสดที่คาสิโนในท้ายที่สุด นั่นเป็นหัวใจสำคัญในการสร้างประสบการณ์ที่ดีของลูกค้าประสิทธิภาพในการดำเนินงานนั้นรู้สึกได้โดยยิ่งไปกว่านั้นในช่วงเวลาสูงสุดเมื่อคาสิโนเห็นการจราจรบนเท้าที่สูงขึ้นการขโมยกรรมและการคดโกงเป็นภัยคุกคามด้านความปลอดภัยอย่างสม่ำเสมอ โดยการมุ่งเน้นไปที่ขั้นตอนการจัดการเงินสด ระบบเฝ้าระวังและเทคโนโลยีอื่นๆเพื่อตรวจค้นและป้องกันกิจกรรมการฉ้อฉลเป็นสิ่งสำคัญอย่างยิ่งสำหรับธุรกิจ

แน่นอนว่าความไว้วางใจและชื่อเสียงของคาสิโนขึ้นกับความเร็วและความปลอดภัยของธุรกรรมเหล่านี้นอกเหนือจากนี้แน่นอนว่าคาสิโนอยู่ภายใต้การปฏิบัติตามกฎเกณฑ์ในพื้นที่นี้

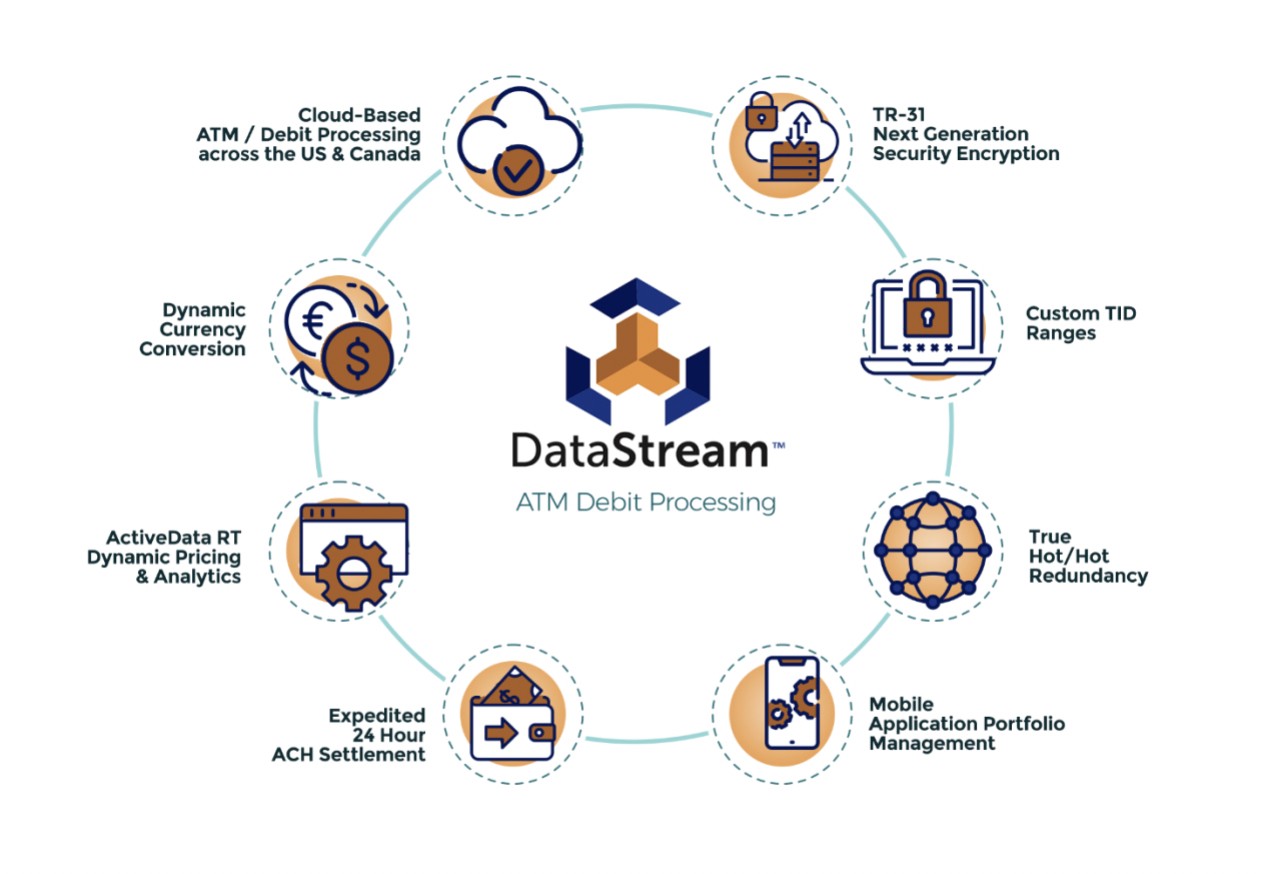

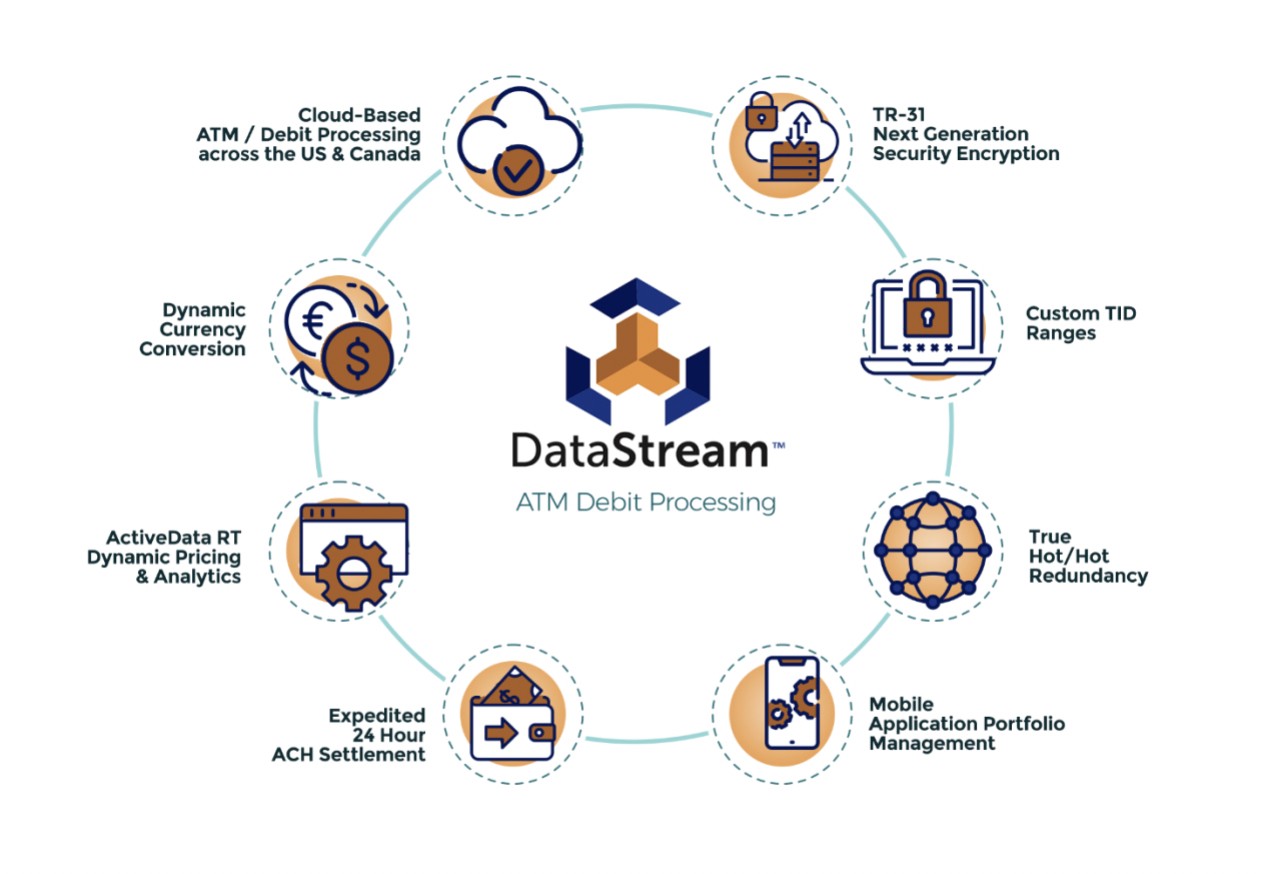

ผู้คนที่ Passport Technology Inc. ผู้ให้บริการเทคโนโลยีการชำระเงินที่เติบโตอย่างเร็วทันใจให้กับอุตสาหกรรมเกมระดับโลกรู้ทั้งหมดนี้DataStream ซึ่งเป็นโซลูชันการจัดการและเข้าถึงเอทีเอ็มที่เป็นกรรมสิทธิ์ของ Passport ขณะนี้เปิดให้บริการที่คาสิโนทั่วสหรัฐอเมริกาและแคนาดาโดยมีการขยายไปยังสหราชอาณาจักร

DataStream เปิดตัวในปี 2003 ในสหรัฐอเมริกา (พวกเขาเริ่มให้บริการประมวลผลให้กับคาสิโนในปี 2008) ได้กลายเป็นหนึ่งในโปรเซสเซอร์ ATM ที่เป็นกรรมสิทธิ์ที่เติบโตเร็วที่สุดและได้รับการสนับสนุนจากธนาคาร ซึ่งอำนวยความสะดวกในการประมวลผลธุรกรรม ATM, POS และ Value-Add ให้กับลูกค้าค้าปลีกและการเล่นเกม

ในปี 2020 DataStream ได้เป็นผู้ก่อตั้งสโผลงปัตยกรรมการประมวลผลบนคลาวด์ที่เป็นนวัตกรรมใหม่และเต็มรูปแบบเพื่อให้ลูกค้าประมวลผลมีความน่าไว้ใจระดับที่ไม่มีใครเทียบได้ การเพิ่มจำนวนเงินอัตโนมัติ เวลาทำงาน และความปลอดภัยในการประมวลผลที่ไม่สามารถใช้ได้ในสภาพแวดล้อมที่โฮสต์แบบดั้งเดิม

CDC Gaming Reports ได้เจอกับ John Steely ประธานเจ้าหน้าที่ลูกค้าและประธานเจ้าหน้าที่สารสนเทศ และ Kent Cain รองประธานอาวุโส ฝ่ายปฏิบัติการแพลตฟอร์ม เกี่ยวกับจุดกำเนิดของ DataStream และว่าเทคโนโลยีของบริษัทมีความเหมาะสมและปรับตัวได้อย่างสมบูรณ์ในอุตสาหกรรมเกมที่กำลังเติบโตและพัฒนาอย่างรวดเร็วทันใจ

ตามข้อมูลของ American Gaming Association มีคาสิโน 1,011 แห่งในสหรัฐอเมริกาโดยมีผลกระทบทางเศรษฐกิจ 328.6 พันล้านดอลลาร์

โปรเซสเซอร์ เอทีเอ็ม คือสิ่งที่เชื่อมต่อคุณกับธนาคารของคุณตู้เอทีเอ็มจำนวนมากเป็นของสถาบันการเงิน

“มีโปรเซสเซอร์อิสระสองสามตัว” Steely กล่าว“เราก็มีของตนเองสิ่งที่พิเศษเกี่ยวกับพวกเราคือพวกเราสร้างสวิตช์การประมวลผลของเราเองซึ่งเราใช้เพื่ออำนวยความสะดวกในการทำธุรกรรมของพวกเราเอง”

เป็นเครื่องเอทีเอ็มทางกายภาพได้แก่เดียวกับซุ้มมัลติฟังก์ชั่นระบบกรงระบบแบ็คออฟฟิศ ทั้งหมดเชื่อมต่อเพื่อดำเนินการประมวลผลและส่งธุรกรรมผ่านสวิตช์

“สถาปัตยกรรมภายในของพวกเราสำหรับสวิตช์นั้นเชื่อมต่ออัปสตรีมเพื่อให้ธุรกรรมพวกนั้นไปยังโครงข่ายและอำนวยความสะดวกในการทำธุรกรรมเหล่านั้นกลับสู่สภาพแวดล้อมการเล่นเกมได้อย่างเร็ว เพื่อให้แขกสามารถเข้าถึงเงินสดได้” Cain กล่าวเสริม

นั่นคือข้อได้เทียบที่ Passport Technology Inc. และ DataStream มี: เป็นสวิตช์และสโผลงปัตยกรรมที่สร้างขึ้นเพื่ออำนวยความสะดวกในการทำธุรกรรมการเข้าถึงเงินสดเฉพาะที่ไม่เหมือนใครในสภาพแวดล้อมการเล่นเกม

“ประการแรกคือพวกเราต้องรักษาความปลอดภัยการทำธุรกรรมด้วยวิธีที่ไม่เหมือนใคร” เคนกล่าว“ดังนั้นจากตำแหน่งการจัดการการปฏิบัติตามระเบียบและการฉ้อฉล พวกเรามีคุณสมบัติพิเศษภายในสวิตช์ของพวกเราซึ่งจะช่วยปกป้องสภาพแวดล้อมการเล่นเกมในระดับที่ลึกกว่าการประมวลผลตู้เอทีเอ็มปลีกทั่วไป

“ประการที่สองจะเป็นความซ้ำซ้อนฉะนั้นสภาพแวดล้อมการเล่นเกมจึงเจริญเติบโตได้ในเวลาใช้งาน 100 เปอร์เซ็นต์เป็นสิ่งสำคัญจากระดับสวิตช์ที่ระบบการเข้าถึงเงินสดยังคงใช้งานได้และพร้อมใช้งานกับคาสิโนในร้อยละ 100 ของเวลาดังนั้นจึงเป็นเรื่องของการสร้างความล้มเหลวอัตโนมัติพวกนี้ซึ่งไม่มีอยู่ในสวิตช์อื่นๆแต่ให้บริการสภาพแวดล้อมการเล่นเกมโดยยิ่งไปกว่านั้น”

สำหรับลูกค้าคาสิโนของพวกเขา “ถาม” ที่ใหญ่ที่สุดคือ “คุณจะพร้อมสำหรับฉันหรือไม่?”มันเป็นเวลาเปิดใช้งาน คุณมีอะไรบ้าง คุณให้คาสิโนเข้าถึงเงินสดได้ตลอดเวลาได้อย่างไรตลอดเวลาและ DataStream จะมีผลให้การทำธุรกรรมเงินสดของคาสิโนดูแตกต่างและดียิ่งกว่าธุรกรรมเงินสดของคาสิโนอื่นๆได้อย่างไร

“นั่นเป็นหนึ่งในข้อได้เปรียบเทียบที่ยิ่งใหญ่ที่สุดของ DataStream ในวันนี้” Cain กล่าวเสริม“DataStream และ Passport Technology ซึ่งเป็นผู้สร้างซุ้มและซอฟต์แวร์ที่อำนวยความสะดวกในการทำธุรกรรม ทำงานด้วยกันอย่างราบรื่นเพื่อสร้างโฟลว์จากประเภทธุรกรรมที่ปรับแต่งตัวแปรบนพื้นจนถึงเครือข่ายการประมวลผลและการอนุญาตและกลับไปยังเทอร์มินัลเอง

“นั่นทำให้เรามีความสามารถที่ไม่เหมือนใครในการปรับแต่งฟังก์ชันและการทำธุรกรรมและสร้างธุรกรรมประเภทใหม่และการทำธุรกรรมที่ทำหน้าที่เป็นแขกและลูกค้าและยังสามารถสร้างรายได้เพิ่มเติมให้กับคาสิโน”

ในทางกลับกัน ถ้าเกิดคาสิโนขนาดกลางที่ทำงานกับโปรเซสเซอร์ขนาดใหญ่ต้องการเปลี่ยนขั้นตอนการทำธุรกรรมด้วยการถอนเงินตัวอย่างเป็นต้นว่าหรือเพื่อให้รายงานดูเป็นทางใดทางหนึ่ง Passport สามารถทำการเปลี่ยนแปลงนั้นให้เขาได้โดยเหตุนั้นการเปลี่ยนแปลงการปรับตัวในการดำเนินงานระหว่างการวิ่งสำหรับคาสิโนที่เกี่ยวข้องกับการขยายจำนวนการจราจรบนเท้าจึงเป็นสิ่งสำคัญด้วยคาสิโนขนาดกลางที่ทำงานกับหนึ่งในโปรเซสเซอร์ขนาดใหญ่พวกเขาจะไม่เปลี่ยนกระแสของคาสิโนนั้นด้วยเหตุว่ามันไม่สมเหตุสมผลทางเศรษฐกิจสำหรับพวกเขา

“พวกเขามีธุรกรรมหลายแสนคนถ้าเกิดไม่ใช่หลายล้านรายการและพวกเขาจะไม่ทำการเปลี่ยนแปลงกระแสสำหรับคาสิโนขนาดกลาง” Steely กล่าว“มันเป็นการพัฒนามากเกินไป เวลามากเกินไปมันไม่คุ้มค่าสำหรับพวกเขาแต่ส่วนตัวเราเพราะว่านั่นคือลูกค้าของพวกเรามันคุ้มค่าส่วนตัวเราด้วยเหตุดังกล่าวพวกเราจะทำการเปลี่ยนแปลงนั้นให้พวกเขาพวกเราทำสิ่งนี้ตลอดเวลา”

การมีความคล่องตัวและสามารถปรับแต่งได้ทันที นั่นคือความแตกต่าง – ผู้สร้างในอุตสาหกรรมที่แข่งขันได้ Steely กล่าวเสริม

“ลูกค้าของพวกเราดูเหมือนจะทุกคนขอสิ่งที่ไม่เหมือนใครและเราจัดส่งทุกครั้ง” เขากล่าว

ข้อดีอย่างหนึ่งที่พวกเขามีคือรอยเท้าเทคโนโลยีทั้งหมด เพราะฉะนั้นแอปพลิเคชันทั้งหมด การประมวลผลและสภาพแวดล้อมโครงข่ายทั้งหมด จึงอยู่ในสถาปัตยกรรมบนคลาวด์นั่นเป็นเรื่องหายาก

“มันพูดถึงความซ้ำซ้อนอีกทีที่คลาวด์เองมีระบบรักษาความปลอดภัยในตัวขนาดใหญ่และระบบตรวจสอบการหลอกลวง” Cain กล่าว“แต่ในเวลาเดียวกัน มันยังล้มเหลวโดยอัตโนมัติในหลายวิธีที่สภาพแวดล้อมภาคพื้นดินไม่ทำเช่นเดียวกัน พูดถึงเวลาทำงานสำหรับผู้ให้บริการอีกครั้ง”

คำถามเกี่ยวกับความปลอดภัยกำลังพัฒนาขึ้น เมื่อหลายปีที่ผ่านมาคาสิโนถามว่าผู้ให้บริการจะรักษาความปลอดภัยข้อมูลของผู้ถือบัตรหรือไม่ โดยเหตุนั้นจึงไม่ได้นำมาจากสภาพแวดล้อมของคาสิโน ไปจนถึงสิ่งที่พวกเขาถามเพิ่มเติมในทุกวันนี้ — ผู้ให้บริการ ATM ปฏิบัติตามขอบเขตของ PCI (อุตสาหกรรมบัตรชำระเงิน) หรือไม่ ตั้งแต่พื้นไปจนถึงการสลับไปยังเครือข่ายผู้ประกอบการคาสิโนทราบดีว่านั่นคืออะไรและความลึกของมันและทราบดีว่ามันหมายถึงความปลอดภัยของข้อมูลแขกของพวกเขา

การเติบโตของ บริษัท?Passport Technology Inc. มุ่งเน้นไปที่สหรัฐอเมริกาแคนาดาและสหราชอาณาจักรอย่างเท่าเทียมกัน ปรับปรุงและพัฒนาอย่างรวดเร็วเพื่อตอบตอบสนองภูมิทัศน์คาสิโนที่เปลี่ยนแปลง

“จากมุมมองด้านเทคโนโลยีฉันสามารถสร้างเทคโนโลยีนี้ได้หลากหลายเท่าใด”เคนกล่าว“ฉันจะทำสิ่งนี้ได้อย่างไร เพื่อให้เราเปลี่ยนแปลงอย่างต่อเนื่องเพื่อตอบตอบสนองภูมิทัศน์ที่เปลี่ยนแปลงไปพร้อมทั้งธุรกรรมและเทคโนโลยี?สิ่งที่เราต้องทำคือสร้างสถลาปัตยกรรมแบบแยกส่วนเพื่อให้พวกเราสามารถอัปเดตและเสียบจุดใหม่ได้อย่างต่อเนื่อง

“การปฏิบัติตามกฎระเบียบมีการเปลี่ยนแปลงอย่างรวดเร็วและถ้าหากคุณเป็นสวิตช์ที่ติดอยู่ในสิ่งที่พวกเขาเรียกว่าสถาปัตยกรรมสแต็คหรือแม้แต่สถาปัตยกรรมสแต็คภาคพื้นดิน คุณจะไม่สามารถใช้การเปลี่ยนแปลงใหม่ที่จำเป็นเพื่อให้สอดคล้องกับความคล้ายคลึงได้

“สิ่งเดียวกันสามารถกล่าวได้สำหรับชุดธุรกรรมใหม่ ไม่ว่าจะเป็นกระเป๋าเงินตามจุดสูงขึ้นตามความภักดี ผลิตภัณฑ์ทั้งหมดพวกนั้นต้องเสียบในลักษณะที่สามารถใช้งานได้ง่ายและเร็วเพราะฉะนั้นการสร้างสโผลงปัตยกรรมที่เหมาะสมเพื่อให้สิ่งต่างๆสามารถย้ายปรับเปลี่ยนและอัปเดตได้โดยไม่ต้องสร้างมรดกที่ช้าในการเพิ่มขึ้นตามความต้องการด้านเทคโนโลยีของธุรกรรมพวกนี้เป็นสิ่งสำคัญอย่างยิ่ง”